This is the beginning of the fabrication of the boat's mainsail boom. It's glued up from two pieces of 3 inch by 1 1/2 inch by 12 foot something Douglas Fir. Lots of clamps are needed for this process.

Once the clamps come off the planer smoothes up the squeezed out glue and gives a good surface for marking the profile of the boom. The top surface of the boom remains straight to accommodate the sail while the other sides are tapered as per the plans. The tarp keeps the discharge from the planer under control and makes cleanup easier.

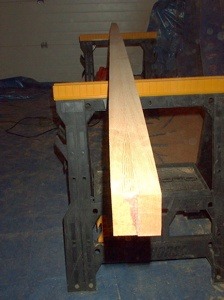

And this is what it looks like once the power planer is done with it. Planers are great tools but they can take a lot of wood off quickly. Check often to be sure you are keeping the spar square, too.

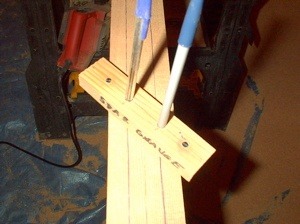

Once all four sides of the spar are tapered according to the plans, a spar gauge is used to prepare the spar for eight siding. Most boat building books tell how to make one of these. This one is from Iain's book.

The boom is now marked on all four faces and is placed for power planing the corners off. Careful work is needed during this step.

One down, three to go. The first corner is removed. More material needs to be removed from the center of the spar than the ends, so be ready to leave the ends alone early on in the shaping. I didn't do it, but it would probably be best to plane the last bit by hand, just to be sure to get it right

From here I work by hand and eye. First the spar is taken to 16 sides then I work along the spar feeling for the corners and ridges and carefully trimming them off with a very sharp and fine block plane. I try to take it as far as I can with the plane. At this point I switch to sandpaper.

This rather primitive device is the sanding drum I use to sand the last ridges off the spar. The drum is a 4 x 4 piece of cedar I had (rounded like a spar), two cutouts from port lights cap the ends, a length of threaded rod holds it together, and a short length of steel pipe forms a handle. I taped the center with cloth athletic tape for grip to the inside of the sanding belts. It works OK but is too wide for the 3 inch belts, works better with the 4 inch ones. Beats sanding the things by hand. The down side is that there are lots of cross grain scratches that will have to be sanded out by hand.

Next the mast band (sail out haul, sheeting) is fitted to the aft end of the boom. It has to be 4 inches from the end and has a shallow shoulder for its forward edge to butt against. I fit it a little loose to allow for the thickness of the finish coats of varnish.

Of course there has to be a fitting at the other end too. This is the bronze spar end from Classic Marine that will attach to the gooseneck, also from Classic Marine. I'll have to drill holes in all the spar fittings for fasteners. Note that the spar had to be rounded to fit the gooseneck fitting.